Understanding Aluminum Busbars: A Comprehensive Guide

At AP Precision Metals, we pride ourselves on delivering top-tier metal solutions tailored to meet diverse industrial needs. Today, we delve into the world of aluminum busbars, a critical component in electrical systems that has garnered widespread attention for its efficiency and cost-effectiveness. Whether you’re an industry professional or a curious reader, this comprehensive guide will provide you with an in-depth understanding of aluminum busbars, their applications, benefits, and comparisons with other materials.

What Are Aluminum Busbars?

Contents

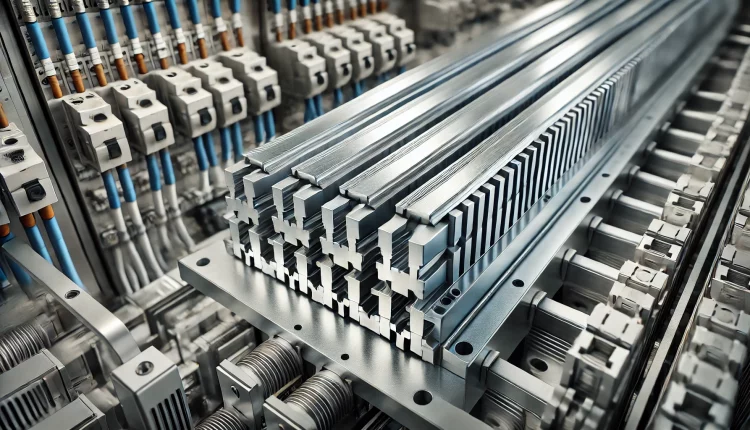

Aluminum busbars are metallic strips or bars made from aluminum, primarily used for conducting electricity within a variety of electrical installations. These busbars serve as essential connectors in power distribution systems, ensuring efficient transmission of electrical currents from one point to another. Their design typically involves flat, solid strips that offer a large surface area, facilitating excellent conductivity and minimizing resistance.

Applications of Aluminum Busbars

The versatility of aluminum busbars makes them suitable for numerous applications, including:

- Power Distribution Systems: They are widely used in electrical panels and switchgear to distribute power efficiently.

- Renewable Energy Systems: In solar and wind energy setups, aluminum busbars play a pivotal role in connecting and distributing power.

- Transportation: They are used in electric vehicles (EVs) and railway systems for power transmission.

- Industrial Facilities: Aluminum busbars are integral in factories and plants, managing the power needs of heavy machinery.

Benefits of Aluminum Busbars

Aluminum busbars offer several advantages that make them a preferred choice in various industries. These benefits include:

- Cost-Effectiveness: Aluminum is less expensive compared to other metals like copper, making aluminum busbars a budget-friendly option without compromising on performance.

- Lightweight: Aluminum’s lower density means that busbars made from this material are lighter, which is particularly beneficial in applications where weight reduction is crucial, such as in aerospace and automotive industries.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that guards against corrosion, enhancing the longevity and reliability of busbars in harsh environments.

- Excellent Conductivity: While copper is often considered the gold standard for electrical conductivity, aluminum provides a highly efficient alternative that meets the rigorous demands of modern electrical systems.

- Flexibility: Aluminum busbars are easy to shape and customize, allowing for tailored solutions that meet specific design requirements and space constraints.

Aluminum Busbars vs. Copper Busbars

One of the most common debates in the realm of electrical components is the comparison between aluminum busbars and copper busbars. Each material has its unique properties and suitability for different applications. Let’s break down the key differences:

- Conductivity: Copper boasts higher electrical conductivity than aluminum. However, aluminum busbars compensate for this with their larger surface area, providing adequate conductivity for many applications.

- Weight: Aluminum is significantly lighter than copper, which can lead to easier handling and installation, as well as reduced structural support requirements.

- Cost: The cost of aluminum is generally lower than that of copper, making aluminum busbars a more economical choice, especially for large-scale projects.

- Thermal Expansion: Aluminum expands more than copper when heated. This property must be considered in designs to prevent issues related to thermal expansion and contraction.

- Corrosion Resistance: Aluminum naturally resists corrosion, while copper may require additional coatings or treatments to enhance its durability in corrosive environments.

Installation and Maintenance of Aluminum Busbars

Proper installation and maintenance are crucial for the optimal performance of aluminum busbars. Here are some best practices to ensure longevity and reliability:

- Jointing and Connections: Ensure that joints and connections are secure to prevent overheating and electrical losses. Using appropriate connectors and maintaining tight connections are vital.

- Coating and Insulation: Apply suitable coatings and insulation to protect against environmental factors and mechanical damage. This step is especially important in outdoor and industrial settings.

- Regular Inspections: Conduct routine inspections to detect any signs of wear, corrosion, or loose connections. Early detection can prevent potential failures and extend the lifespan of the busbars.

- Thermal Management: Implement effective thermal management strategies to dissipate heat generated during high-current operations. Adequate ventilation and heat sinks can help maintain optimal operating temperatures.

Innovations and Future Trends in Aluminum Busbars

The ongoing advancements in material science and manufacturing processes continue to enhance the performance and applications of aluminum busbars. Some emerging trends and innovations include:

- Advanced Alloys: Development of new aluminum alloys with improved conductivity and strength, tailored for specific applications.

- Sustainable Manufacturing: Emphasis on eco-friendly production methods and recycling practices to reduce the environmental impact of aluminum busbar manufacturing.

- Smart Busbars: Integration of sensors and monitoring systems within busbars to provide real-time data on performance, enabling proactive maintenance and fault detection.

Conclusion

Aluminum busbars represent a vital component in modern electrical systems, offering a balance of cost, efficiency, and reliability. Their wide range of applications, from renewable energy systems to industrial facilities, underscores their versatility and importance. By understanding the benefits, installation practices, and emerging trends, you can make informed decisions about incorporating aluminum busbars into your projects.

At AP Precision Metals, we are committed to providing top-quality aluminum busbars that meet the highest standards of performance and durability. Our expertise in metal solutions ensures that you receive the best products and support for your electrical needs.

For more information on aluminum busbars and how they can benefit your specific applications, feel free to contact our team at AP Precision Metals. We are here to assist you with expert guidance and customized solutions.

Aluminum Busbars in Electrical Systems

Aluminum busbars are a crucial element in electrical systems, offering a myriad of benefits that make them an ideal choice for various applications. As a cost-effective and lightweight alternative to copper, aluminum busbars provide excellent conductivity and corrosion resistance. Their adaptability and ease of installation make them a preferred option for power distribution, renewable energy systems, and transportation sectors. By incorporating aluminum busbars, industries can achieve efficient and reliable power transmission while keeping costs under control.

Whether you are looking to upgrade your existing electrical infrastructure or planning a new installation, considering aluminum busbars can lead to significant advantages in terms of performance and longevity. At AP Precision Metals, we specialize in providing high-quality aluminum busbars tailored to meet your specific needs. Contact us today to learn more about how aluminum busbars can enhance your electrical systems.

Comments are closed.